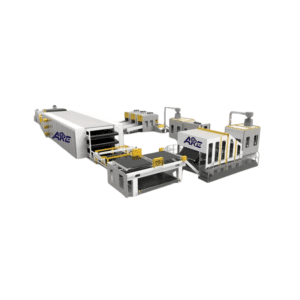

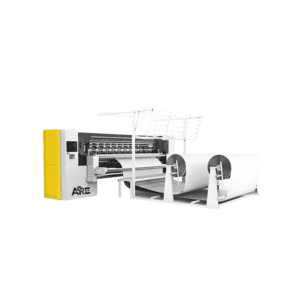

High speed shuttle quilting machine

Applications:

CS66 series quilting machines are used for garments, winter-jackets, winter wear pajamas, car mat, car cushion protectors, handbags, oven gloves, shoes covers and outdoor sleeping bags etc.

Description

High-Speed Shuttle Type Quilting Machine

Working Principle

A high-speed shuttle type quilting machine utilizes a rotating shuttle to drive the bobbin thread and needle thread to interweave, forming a firm stitch that sews together the three layers of a quilt (top fabric, batting, and backing). During operation, the needle carries the upper thread through the quilt materials, while the shuttle rotates below the needle to catch the upper thread and interlock it with the bobbin thread, completing the formation of a stitch. This cycle repeats to achieve quilt sewing.

Characteristics

- High Speed and Efficiency: Capable of running at high speeds, reaching hundreds or even thousands of stitches per minute, significantly improving production efficiency. It is suitable for large-scale quilt manufacturing.

- Firm Stitches: Adopting a shuttle structure, the formed stitches are strong, able to withstand the stretching and friction during the quilt’s use, ensuring the quilt’s service life.

- Diverse Patterns: Typically equipped with multiple stitch length and pattern selection functions, controlled by computer programs to achieve 360-degree pattern quilting, meeting different users’ needs for quilt design.

- Strong Stability: Featuring a sturdy machine structure and stable transmission system, it maintains good stability during high-speed operation, reducing vibration and noise to ensure quilting quality.

- Wide Applicability: Adapts to fabrics and battings of different thicknesses and materials. By adjusting parameters such as presser foot pressure and stitch length, it can process various quilts, from thin silk quilts to thick cotton quilts.

Application Fields

- Bedding Manufacturing: Used for producing various quilts, mattresses, bedspreads, etc., providing beautiful quilting patterns and good warmth retention and durability for bedding.

- Home Decorations: Applicable to quilting processes for curtains, sofa cushions, throw pillows, and other home decor items, enhancing product aesthetics and texture.

- Garment Processing: In some clothing production, such as winter coats and sleeping bags, high-speed shuttle quilting machines are also used to sew battings, improving the warmth and three-dimensional effect of garments.

- Automotive Interiors: Used for quilting processing of automotive seat covers, headliners, and other interior parts, enhancing the aesthetics and comfort of automotive interiors.

Technical Development Trends

- Increasing Automation: With technological advancements, high-speed shuttle quilting machines are becoming more automated, equipped with functions like automatic feeding, automatic thread break detection, and automatic thread trimming. This reduces manual operation and improves production efficiency and quality stability.

- Intelligent Control: Equipped with advanced computer control systems, operable and programmable via touchscreens or computer software to achieve precise control over the quilting process. They can also be networked with other devices for intelligent production management.

- Energy Conservation and Environmental Protection: In design and manufacturing, greater emphasis is placed on energy conservation and environmental protection, using high-efficiency energy-saving motors and transmission systems to reduce energy consumption and noise pollution.